COMPOSITE POWER LINE PILLARS: START UP OF ACTUAL BUSINESS PROJECT

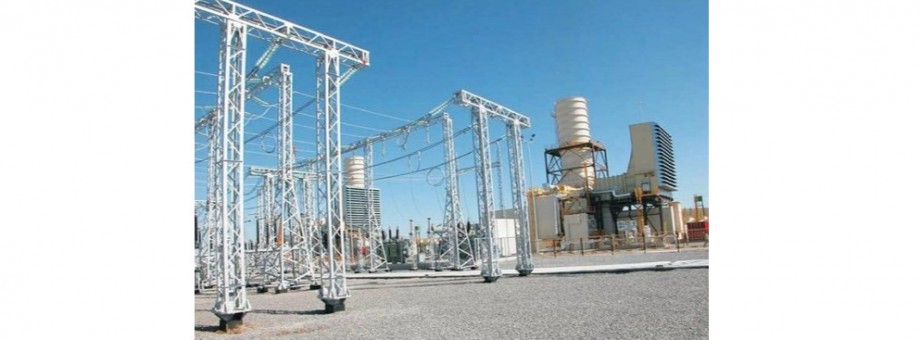

For the first time in the country, steel reinforcement of concrete pillars for power lines was replaced with composite materials. The first shipment of pillars from new material for urban electricity network was produced by the capital Ferro concrete plant.

Workshop for production of fibreglass reinforcement from the wastes of glass production, which has many advantages comparing with metal one, has been opened at the facility located in Byuzmeyin etrap.

Compositenergo Business Entity was an initiator of production of composite pillars for power lines and light masts. Project works were performed by Turkmengosproject Association. Samples of composite reinforcement bar underwent successful test in Scientific and Research Institute of Seismic Construction.

The producers say that enforcement bars from fibreglass are distinguished by low cost, strength, lightweight, chemical and corrosion resistance, low thermal conductivity, dielectric features and long durability, which provide its advantages comparing with metal analogues.

At present time, production capacity of the workshop allows making 170 tons of fibreglass per year. The Compositenergo Business Entity plans to expand the production up to 500 tons per year. For this purpose, the founder – Elektroulgamgurluşik Business Entity invested to procurement of specialized equipment and smelters.

In the future, it is planned to bring the production to 2,500 tons of fibreglass reinforcement bars of various diameter and length per year, which are equivalaent to metal, in the context of realization of the state import substitution programme. It will cover growing requirements of electrical energy industry of the country completely.

NEWS

NEWS